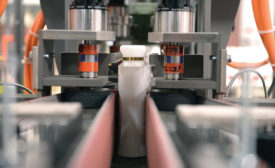

Case Forming/ Packing/ Sealing

Machinery

As suppliers design end-of-line equipment to meet today’s packaging needs, the industry holds great promise to close the skills gap.

Read More

Materials

Vacuum Skin Packaging for Premium Foods

VSP accommodates differently shaped products and sharp edges, and it can skin pack with paperboard, offering more options.

April 11, 2019

Fibre Box Association Column

Engineering Boxes for Relative Humidity in the Distribution Environment

March 20, 2019

Spotlight Feature

2019 Packaging Outlook: The Future Is Now

Part 1 of 6: Consumer habits, new technology and machinery changes provide exciting opportunities, along with some challenges, for the packaging market.

March 12, 2019