Inspection/Detection/Vision

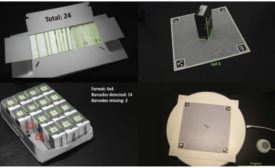

Package Detectability

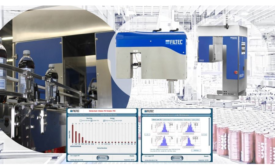

Technology Advances X-ray and Metal Detector Inspection Capabilities

Metal detectors and X-ray machines both have a place on the production line, and different packaging types and products can affect their performance.

March 30, 2021