Home » Keywords: » vision inspection

Items Tagged with 'vision inspection'

ARTICLES

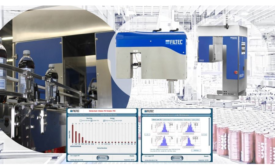

Inspection/Detection

From properly counting out pharmaceuticals to guaranteeing the proper bottling of wine — and even ensuring that the wine bottles themselves are up to snuff — inspection, detection and vision systems play a myriad crucial roles in CPG packaging.

Read More

Vision company revs up 2D barcode reading

Read 2-D matrix and challenging DPM codes even without visible perimeters

December 19, 2014