Beckhoff Automation (beckhoffautomation.com) will showcase system-integrated solutions for IoT and Industrie 4.0 this year at Pack Expo International. In Booth #N-6125, advanced IoT hardware and software technologies from Beckhoff will combine to demonstrate practical implementation of cloud-connected Smart Factory concepts.

Pack Expo will take place from November 6 – 9, 2016 in Chicago’s McCormick Place. Visitors to the Beckhoff booth will have the opportunity to use their own smartphones to interact with PC-based control demos – including the ability to connect with an entire wall of IoT-enabled devices and a 6-axis robot arm using any mobile device with a web browser. For an added level of interactivity, Beckhoff will also show an advanced augmented reality and wearable HMI proof of concept in the form of Microsoft HoloLens™ connected to Beckhoff IoT demos. Visitors to Beckhoff booth N-6125 will have the chance to experience this firsthand and see that, with PC-based control technology, it is already possible to leverage the latest wearable and mobile technologies as another interface to plant floor machinery.

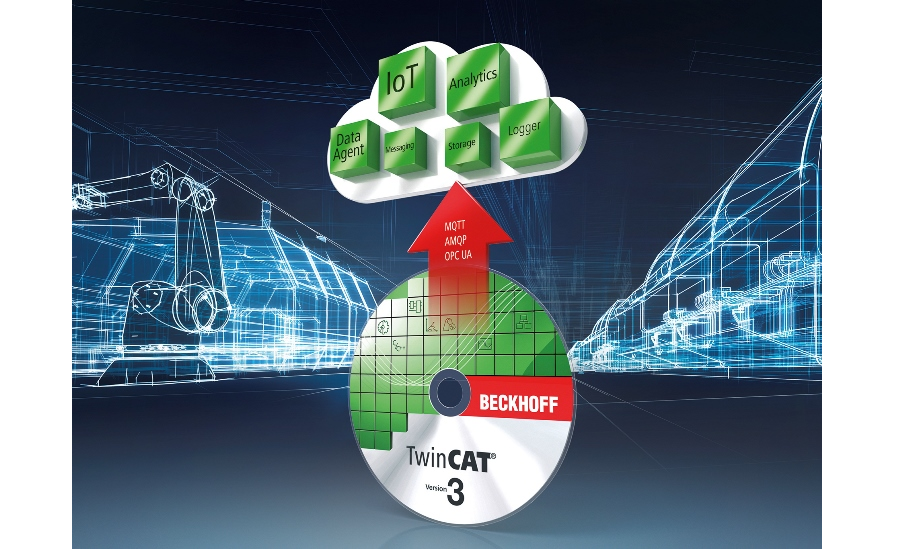

While providing the flexibility to securely transmit plant floor data to cloud services, the Beckhoff approach expands on already-existing systems instead of applying complicated workarounds created with 3rd party developers. TwinCAT 3, the industry-leading PC-based control software platform from Beckhoff, has been expanded to give users the ability to create IoT and cloud-connected automation systems in the same universal environment they program PLC, motion control, robotics, safety technology and more.

In addition, new I/O solutions have been introduced in the form of the Beckhoff IoT Bus Coupler and IoT Box. These provide a simple method to directly connect I/O systems to the cloud and securely transmit data over today’s recognized standards such as OPC-UA, AMQP and MQTT. Additional Smart Factory solutions will factor heavily throughout the Beckhoff booth, such as One Cable Automation, which integrates the previously separate power and signal lines into a single, standard 4-wire Ethernet cable.

“As one of the strongest vertical market trade shows for Beckhoff, Pack Expo continues as a major venue to introduce leading edge automation technologies that are practical and generate real-world results,” says Aurelio Banda, CEO and president, Beckhoff Automation. “As IoT and cloud-connected technologies increasingly shape our packaging and processing conversations, Beckhoff Automation is in a leading position to provide the necessary hardware and software tools that derive value and insight from modern connectivity concepts. These cloud-ready solutions for manufacturers and packaging machine builders efficiently gather all required plant data and provide tools for robust analytics.”

“Plug and Cloud” with the new IoT Bus Coupler from Beckhoff

The new EK9160 IoT Bus Coupler connects Beckhoff EtherCAT I/Os with the Microsoft Azure™ cloud directly, without the need for a specific control program. The coupler offers simple and standardized integration of I/O data with cloud-based communication and data services. The Azure Certified status of the device fulfils an important requirement in this regard for a seamless and easily configured connection via an integrated website to the Azure IoT Hub.

Complete process data acquisition and analysis: TwinCAT Analytics

The Smart Factory introduces numerous requirements for online and offline state analyses, predictive maintenance, pattern recognition, machine optimization and long-term data archiving. This requires data capture to be as continuous as possible and in sync with the processing cycle. That is exactly why Beckhoff developed TwinCAT Analytics software. All process data can be provided as needed, either locally or as a cloud-based solution on a server, whether on an internal corporate network or in a public cloud.

TwinCAT IoT enables fast, standardized cloud communication

With the company’s new TwinCAT IoT software, Beckhoff supports standardized protocols for cloud communication and for sending push messages to smart devices. Quick and easy to configure, TwinCAT IoT provides a variety of functions for exchanging process data via widely-used communication protocols such as AMQP, MQTT and OPC-UA, and for accessing special data and communication services either from public clouds or local systems.

With EtherCAT P, the era of One Cable Automation has arrived

Through EtherCAT P technology, Beckhoff unites EtherCAT communication and power supply in a standard, 4-wire Ethernet cable. Innovative, space-saving One Cable Automation technology integrates the 24 V DC supply of the EtherCAT P slaves with the signals and data from connected sensors and actuators. In addition, the system electrically isolates the US (system and sensor supply) and UP (peripheral voltage for actuators) from each other, each with up to 3 A of current for the connected components. EtherCAT P also represents an important step forward in the effort to make cabinet-free automation systems a reality. Beckhoff offers similar space-saving one cable technologies for industrial displays as well as drives and motors.